Dynamic balancing machine calibration steps

Published:

2019-09-06 09:38

Dynamic balancing machines are a measurement tool that we often use for production. With the advancement of technology and the development of technology, people have used balance machines extensively. We use a dynamic balancing machine to measure balance efficiency. However, when we operate the balancing machine, we must first calibrate it. What are the calibration steps of the dynamic balancing machine?

1. Open the calibration dialog box and enter the weight of the test weight by 0.5g and the angle of 0 degrees. If the left and right corrections should be entered at the same time.

2. Add 0.5g plasticine at 0° on the left calibration surface of the groove according to the weight and angle input on the left side. Do not increase the weight on the right correction surface. Click the calibration measurement button.

3. Start the slot by driving, wait for the lock button to turn green, and start the measurement after unlocking. After the measurement time is completed, lock the car to stop the slot.

4. Press the weight and angle entered on the right side to add 0.5g plasticine to the right correction surface of the drum. The left correction surface is not emphasized. Click the calibration measurement button.

5. Start the slot by driving, wait for the lock button to turn green, and start the measurement after unlocking. After the measurement time is completed, lock the car to stop the slot.

6. Do not add test weight to the left and right calibration surfaces, click the calibration measurement button.

7. Start the slot by driving, wait for the lock button to turn green, and start the measurement after unlocking. After the measurement time is completed, lock the car to stop the slot.

8. Click the calibration completion button and the calibration process ends.

The above is the calibration of the dynamic balancing machine. When we use the dynamic balancing machine, we must carry out good maintenance and maintenance on it, so as to extend its service life.

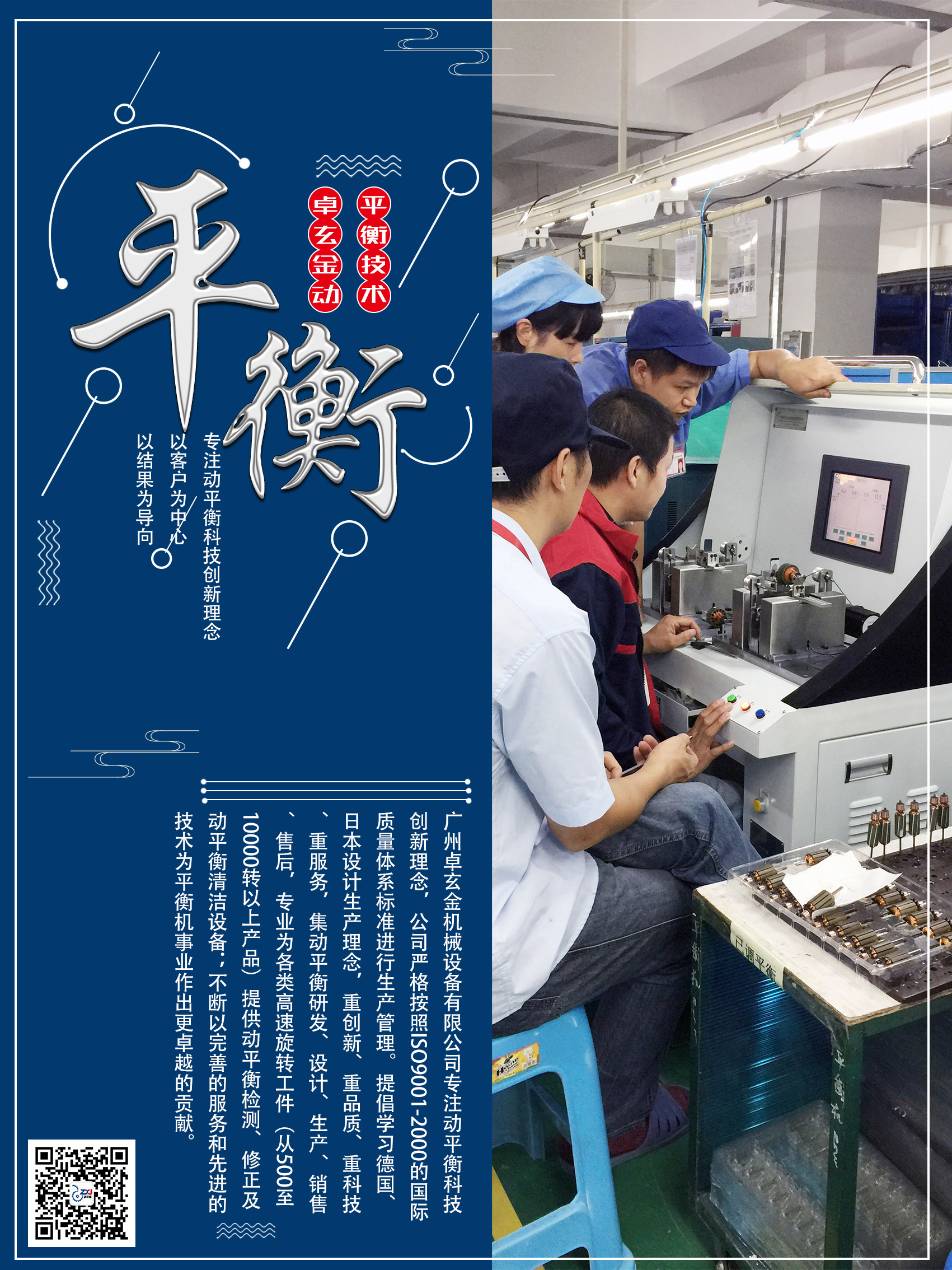

Guangzhou Zhuo Xuanjin engineers reminded that the dynamic balancing machine is a high-precision measuring instrument. The maintenance personnel are required to have certain electrician knowledge, especially the knowledge of weak electricity. For this reason, the professional technicians who choose to identify it should be repaired as much as possible. After-sales service consultation telephone: 020-36969823.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機轉子裝配工的一般操作規程如下: 1、工作前,整理場地,放穩各零、部件,并檢查裝配使用工具和工作環境是否安全良好。 2、吊放電機機座、底板、定子、轉子、軸承等大型部件時必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.