Features of Automatic Balancing Machine System

Published:

2019-12-28 11:32

Fully automatic balancing machine is an instrument for measuring the imbalance of a rotating object (rotor). Centrifugal force due to the uneven mass distribution relative to the centerline when any rotor rotates around its centerline. This unbalanced centrifugal force can cause rotor vibration, noise, and speed up the rotor's service life, leading to equipment failure.

Seriously affect the performance and life of the product. The data measured by the automatic balancing machine can correct the unbalance of the rotor, improve the mass distribution of the rotor relative to the centerline, and reduce the vibration acting on the bearings to an allowable range. Therefore, balancing machines are essential equipment for reducing rotor vibration, improving performance and improving quality.

Features of automatic balancing machine system:

1. The automatic balance machine system is easy to operate, the automatic balance detection is integrated with the CNC cutting system, and the dynamic balance measurement value is automatically calculated as the cutting trajectory.

2. High precision and strong reliability. The automatic balancing machine has the automatic protection function for equipment and milling cutter in case of sudden power failure or milling cutter aging.

3. Pneumatic control technology is used to control the whole process of rotor transmission from lifting, falling to measurement completion.

4. The same display is displayed in the Chinese menu, and the data is automatically stored.

5. In order to solve the traditional transmission problems, due to the uneven bearing surface and the large error in the dynamic balance measurement results, we use the center of the shaft: three bolt holes are applied with high-strength protective sleeves, which not only ensures the transmission force without damaging the screws Holes, and long life, do not need to be replaced frequently.

6. The automatic handling of robotic arms and high-precision measurement and calibration methods are used to completely reduce manual operations to ensure production safety and reduce material waste.

7.It has separate support for rotor, hydraulic oil floating bracket and iron chip receiving board to automatically track when removing weight, complete iron chip recovery, balance measurement and high precision weight removal function.

Ltd. The company specializes in the design, development and sales of automatic balancing machines, automatic positioning dynamic balancing machines, self-driven full-automatic balancing machines, loop-driven balancing machines, universal joint balancing machines, Horizontal dynamic balance machine, vertical dynamic balance machine, on-site dynamic balance instrument, etc., you can also develop various types of dynamic balance machine according to your requirements.

You can also contact our online customer service (qq: 3233915463 // phone: 18933956581 // landline: 020-36969823) We will serve you wholeheartedly and look forward to your contact.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機轉子裝配工的一般操作規程如下: 1、工作前,整理場地,放穩各零、部件,并檢查裝配使用工具和工作環境是否安全良好。 2、吊放電機機座、底板、定子、轉子、軸承等大型部件時必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

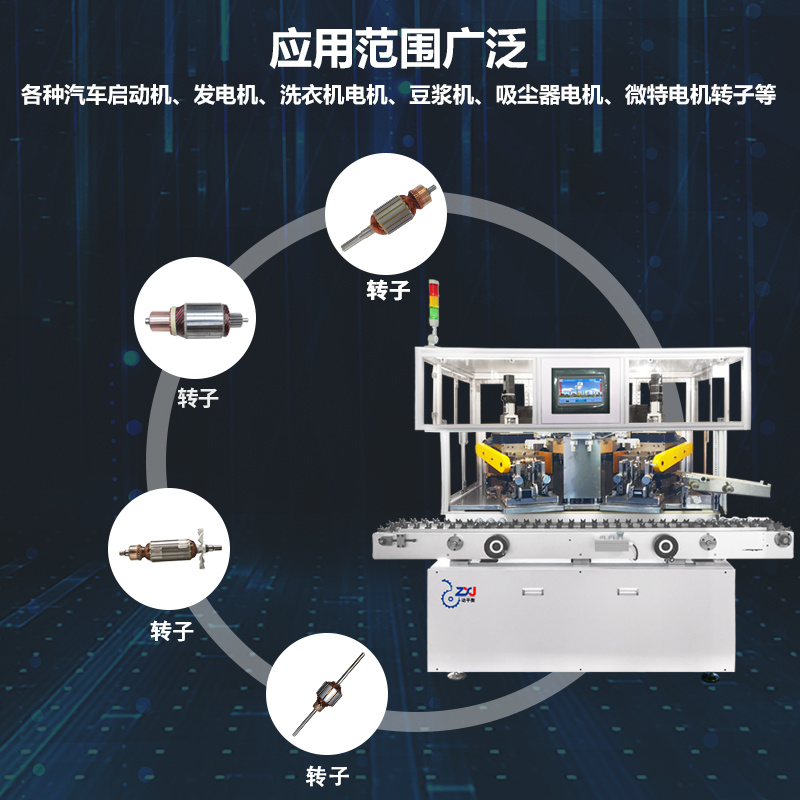

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.