Seven development trends of automatic positioning dynamic balancing machine

Published:

2020-03-31 10:20

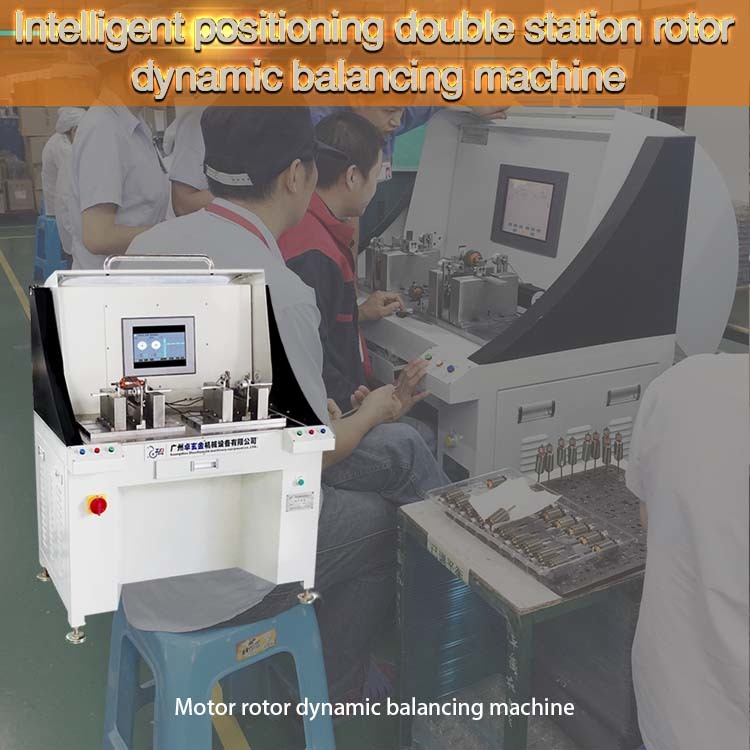

It is expected that in the next few years, automatic positioning dynamic balancing machines will appear in the workshops of various rotating workpiece production industries. Automatic positioning dynamic balancing machines, as intelligent and efficient detection equipment, can reduce manual labor intensity and improve work efficiency. At the same time, some "high-precision tasks" can accurately and quickly complete the measurement and positioning of the dynamic balance of the workpiece. For example, production workshops with high balancing accuracy requirements such as drones, electric spindles, and home appliances introduce automatic positioning dynamic balancing machines to achieve rapid measurement and automatic positioning of unbalanced positions to achieve precision, intelligence, informationization, and shortened measurement workpieces. Correct time, reduce product loss, and reduce investment costs.

1. High speed. The application of new materials in motors, fans, spindles and other industries has increased the requirements for high-speed dynamic balancing machines.

2. Intelligent. Intelligentization and informatization require dynamic balancing machines to improve part processing accuracy and production efficiency, and shorten product manufacturing cycles.

3. High accuracy. The intelligent measurement of dynamic balancing machines is required to improve detection accuracy, positioning accuracy, and repeatability.

4. Informatization. The market needs a dynamic balancing machine with an information storage function. It is very important to ensure that the measurement information is unobstructed when it needs to be viewed.

5. Simple control. Adapted to various manufacturing industries, the simplification of the operation of the automatic positioning dynamic balancing machine is continuously increasing.

6. High reliability. The automatic positioning dynamic balancing machine requires strict manufacturing and clear reliability targets, and analysis of error patterns through measurement repeatability and identification of weak links, continuous improvement and innovation, and increased reliability.

7. Application of multimedia technology. The automatic positioning dynamic balancing machine greatly facilitates the use of non-professional users, and can prompt operations directly through the operation interface menu.

This article is provided by Guangzhou Zhuoxuanjin Machinery Equipment Co., Ltd. The company specializes in the design, development and sales of automatic balancing machines, automatic positioning dynamic balancing machines, self-driven full-automatic balancing machines, loop-driven balancing machines, universal joint balancing machines Horizontal dynamic balance machine, vertical dynamic balance machine, on-site dynamic balance instrument, etc., you can also develop various types of dynamic balance machine according to your requirements.

You can also contact our online customer service (qq: 3233915463 // phone: 18933956581 // landline: 020-36969823) We will serve you wholeheartedly and look forward to your contact.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機轉子裝配工的一般操作規程如下: 1、工作前,整理場地,放穩各零、部件,并檢查裝配使用工具和工作環境是否安全良好。 2、吊放電機機座、底板、定子、轉子、軸承等大型部件時必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.