ndustry Q & A-5 Frequently Asked Questions about Rotor Dynamic Balancing Machines

Published:

2020-04-03 10:53

1. What is the recommended high-precision dynamic balance measurement equipment?

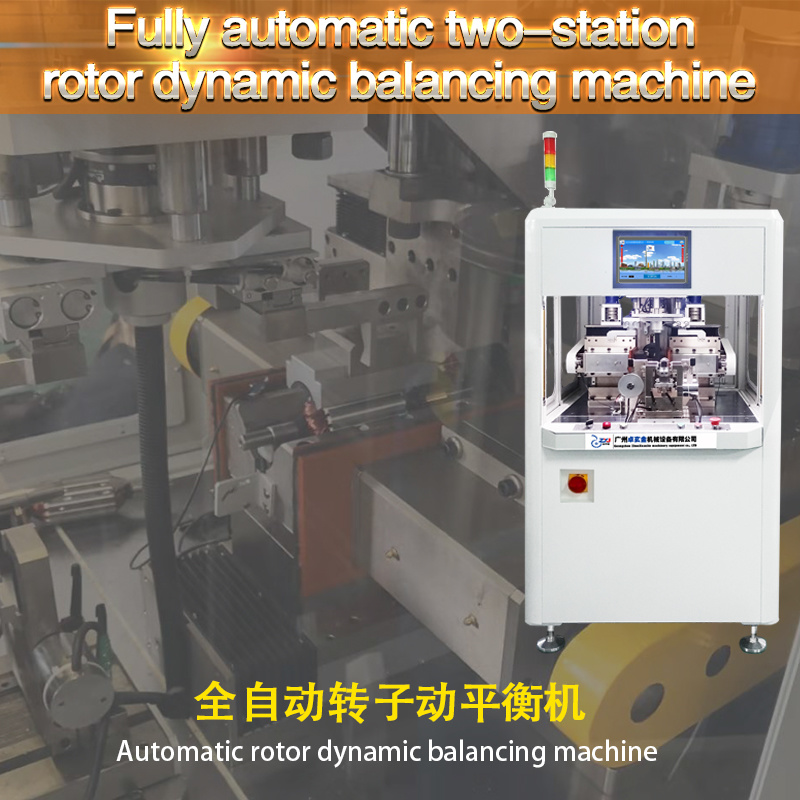

If you want to achieve high-precision measurement quickly, it is recommended to put the automatic positioning dynamic balancing machine directly. At present, the dynamic balancing machine mainly has two technical routes: automatic positioning and automatic. At present, the technology of automatic positioning is relatively mature and the price is relatively low; although the price of fully automatic balancing machines is relatively high, there are not many domestic companies with mature technology. Dynamic balancing machine is a device for measuring the unbalance of rotating workpieces. It can be applied to large and medium-sized rotors, miniature rotors, and blades. Rotating workpieces such as impellers have the advantages of high intelligence, high measurement accuracy, and effective improvement of product quality. Because of its high cost performance and great applicability, it is based on a high-precision sensing system and an electrical measurement system.

2. What are the types of balancing machines?

According to the measurement system, there are: automatic, automatic positioning, self-driving and traditional dynamic balancing machines. According to the measurement methods, there are: horizontal ring with double support dynamic balance machine, horizontal ring with single support dynamic balance machine, vertical dynamic balance machine and on-site dynamic balance instrument. According to measurement accuracy: ordinary dynamic balance machine and high-precision dynamic balance machine (such as automatic positioning dynamic balance machine).

3. How effective is the balancing machine?

The main advantages of the automatic positioning dynamic balancing machine are: 1) effectively improve the product quality and improve the competitiveness of the product market; 2) save labor, the measurement time of the automatic positioning dynamic balancing machine only needs 3 to 5 seconds, and an average of 1-2 traditional dynamic saving Balance machine; 3) Safe and stable, with safety laser detection, effectively reducing the rate of measuring workpiece damage, and ensuring personnel safety. 4) The measurement is stable and reliable, and the position of the rotor unbalance amount can be preset to reduce the number of operation steps and operator calibration errors.

4. What is the price of the balancing machine?

The price cannot be unified, ranging from tens of thousands to millions, depending on the manufacturer's model, customer requirements and measurement accuracy. Generally speaking, the automatic positioning dynamic balancing machine is cheaper than the automatic balancing machine, the traditional dynamic balancing machine is cheaper than the automatic positioning dynamic balancing machine, and the on-site dynamic balancing instrument is cheaper than purchasing the traditional dynamic balancing machine. According to user needs, additional allocations, sensing systems, parts, etc. will affect the final price.

5. Who are the dynamic balancing machine companies? Domestic companies doing balancing machines are mainly concentrated in the Pearl River Delta and the Yangtze River Delta, especially in Guangdong. This has led to the development of the balancing machine industry and the concentration of AI talents. Many companies currently do a full range of dynamic balancing machine products, including fully automatic balancing machines, automatic positioning dynamic balancing machines, self-driven full-automatic balancing machines, transmission dynamic balancing machines, on-site dynamic balancing instruments and non-standard customized dynamic balancing machines. machine. Different dynamic balancing machine products have different requirements for measurement accuracy. Generally speaking, automatic positioning dynamic balancing machines have the highest accuracy requirements, followed by fully automatic balancing machines, self-driven integrated mobile balancing machines, and traditional dynamic balancing machines. The lowest accuracy requirements are On-site dynamic balance instrument. Therefore, companies that can do dynamic balancing machines may not be able to do automatic positioning dynamic balancing machines, which requires a large amount of up-front investment and customer verification.

This article is provided by Guangzhou Zhuoxuanjin Machinery Equipment Co., Ltd. The company specializes in the design, development and sales of automatic balancing machines, automatic positioning dynamic balancing machines, self-driven full-automatic balancing machines, loop-driven balancing machines, universal joint balancing machines Horizontal dynamic balance machine, vertical dynamic balance machine, on-site dynamic balance instrument, etc., you can also develop various types of dynamic balance machine according to your requirements.

You can also contact our online customer service (qq: 3233915463 // phone: 18933956581 // landline: 020-36969823) We will serve you wholeheartedly and look forward to your contact.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機轉子裝配工的一般操作規程如下: 1、工作前,整理場地,放穩各零、部件,并檢查裝配使用工具和工作環境是否安全良好。 2、吊放電機機座、底板、定子、轉子、軸承等大型部件時必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.