If your company is still hesitant on the automatic positioning dynamic balancing machine-please click here

Published:

2020-06-11 11:14

The intelligent measurement system of automatic positioning dynamic balancing machine is rapidly becoming the most important intelligent centrifugal force measurement device in the manufacture of rotating objects (rotors). According to the analysis report of the dynamic balancing machine industry in 2020, the market size of the dynamic balancing machine industry in 2019 will reach several hundred billion yuan, and it is expected to increase by 25% year-on-year. Intelligent measurement of dynamic balancing machines is no longer an emerging trend. It has become the mainstream. 80% of the manufacturing industry will introduce dynamic balancing machine projects to achieve intelligent centrifugal force measurement, improve efficiency, and improve product quality.

How attractive is the automatic positioning dynamic balancing machine for enterprises?

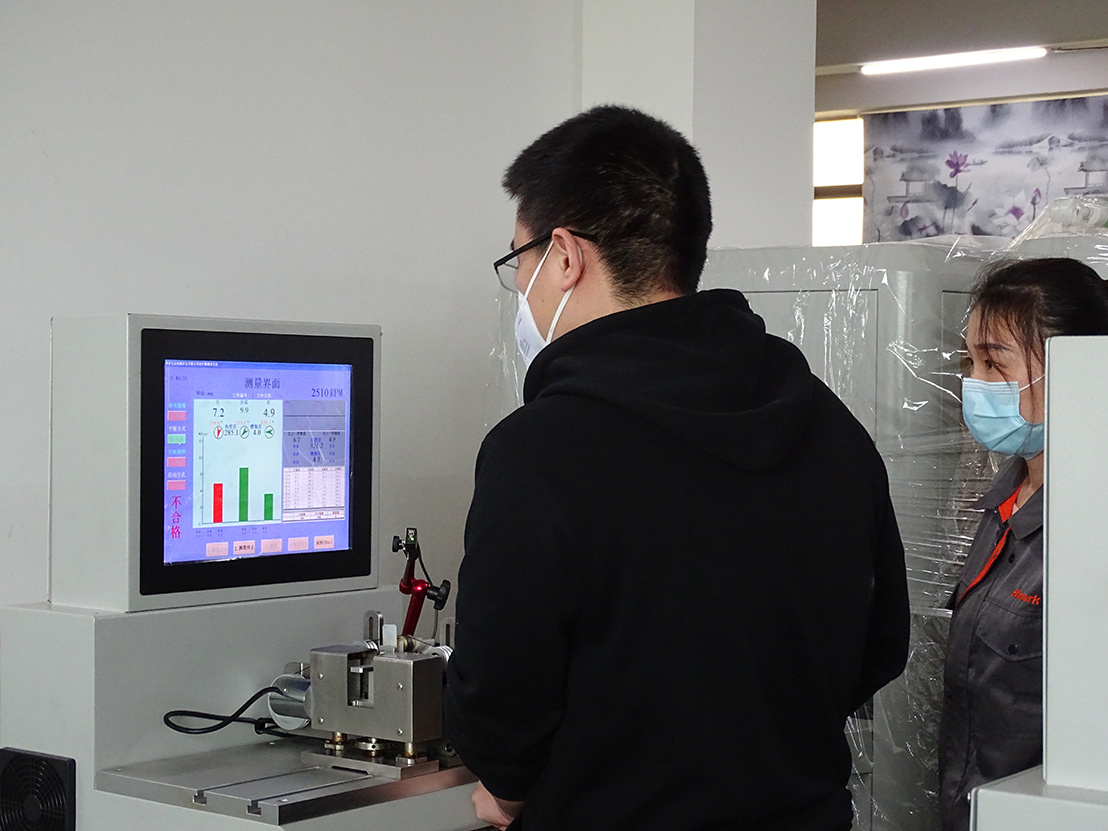

Automatic positioning dynamic balancing machine provides an efficient and intelligent measurement method, which can accurately stop the measurement of rotor unbalance angle at a specified position, thereby greatly improving the efficiency of dynamic balance correction and decelerating correction errors. Compared with the traditional dynamic balancing machine that requires a lot of manpower, low efficiency, complicated operation, and low measurement accuracy, the automatic positioning dynamic balancing machine not only ensures efficient and accurate positioning of the rotor measurement, simple operation, but also saves labor costs.

The automatic positioning dynamic balancing machine can realize the intelligent measurement of the rotor dynamic balance, which greatly improves the intelligence of the production line and has become a smart factory and a smart workshop. In the production of the rotor manufacturing industry, the automatic positioning dynamic balancing machine is used to replace the traditional dynamic balancing machine for measurement, correction, and retesting. The measurement accuracy is higher and the measurement repeatability is more stable, which greatly improves the level of production intelligence and products. quality.

Automatic positioning dynamic balancing machine conforms to the future trend of manufacturing industry

The development of intelligent manufacturing The manufacturing industry also continuously improves the performance and function requirements of automatic positioning dynamic balancing machines. The traditional dynamic balancing machine will be gradually replaced by a more precise and efficient automatic positioning dynamic balancing machine. Zhuoxuanjin automatic positioning dynamic balancing machine is superior to the traditional dynamic balancing machine in terms of measurement accuracy, coordination with the overall production cycle, stability of the measurement system and reliability of data collection, which can make the entire rotor dynamic balance measurement system The operation is more flexible, controllable, efficient and reliable, so it is increasingly favored by the manufacturing industry.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機轉子裝配工的一般操作規程如下: 1、工作前,整理場地,放穩各零、部件,并檢查裝配使用工具和工作環境是否安全良好。 2、吊放電機機座、底板、定子、轉子、軸承等大型部件時必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.