What are the advantages of automatic positioning dynamic balancing machine?

Published:

2020-07-09 10:50

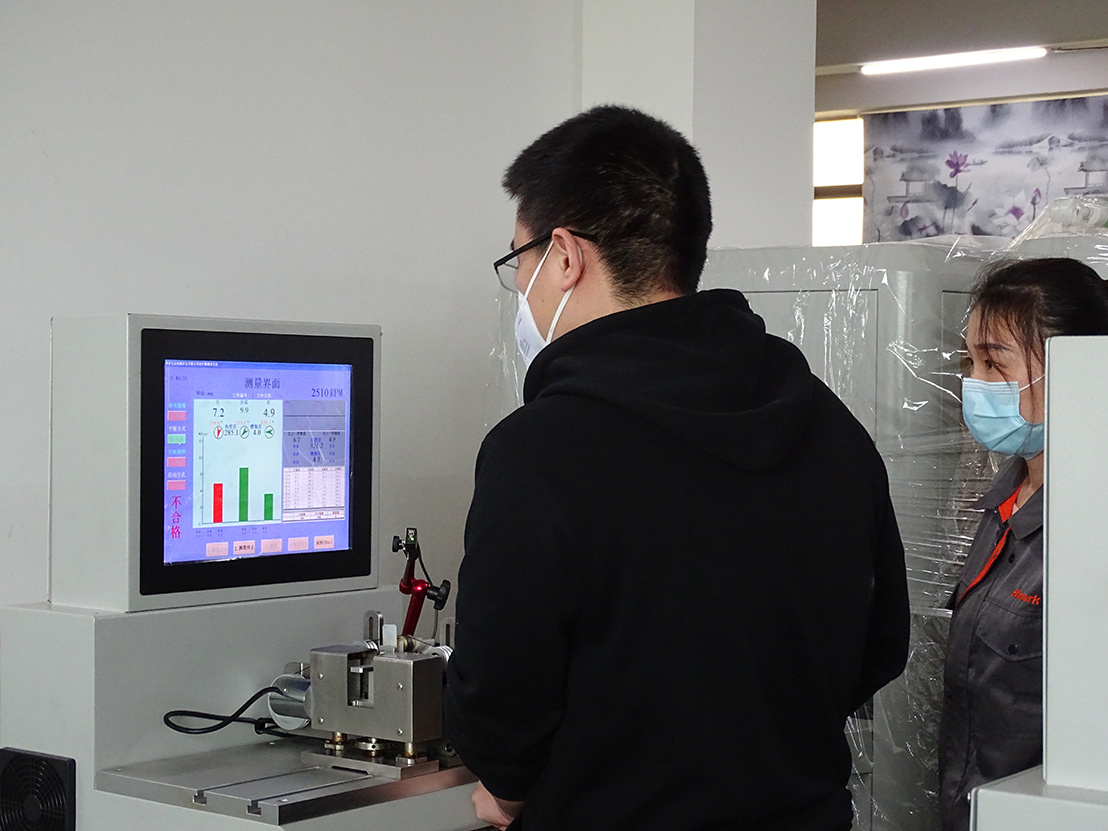

The automatic positioning dynamic balancing machine is the core equipment for improving the quality of the rotating workpiece (rotor) in the intelligent manufacturing system and automatic measurement system. It can autonomously position according to the unbalanced position set in advance and stop the measurement of the unbalanced angle of the rotor at the specified Position, to achieve intelligent measurement and precise positioning of the rotor in the production process. So what are the advantages of automatic positioning dynamic balancing machine?

The automatic positioning dynamic balancing machine can not only improve product quality, reduce labor intensity, improve production efficiency, but also reduce production costs. Like computer and network technologies, the wide application of automatic positioning dynamic balancing machines is increasingly changing the manufacturing methods of manufacturing. The advantages of the automatic positioning dynamic balancing machine are summarized as follows:

1. Improve working conditions

The automatic positioning dynamic balancing machine can accurately position and measure the rotor unbalance angle, and stop the measured unbalance angle at the specified position, which can avoid the correction error caused by human operation fatigue or negligence, inexperience and other factors.

2. Reduce manpower and facilitate rhythmic production

The automatic positioning dynamic balancing machine replaces the traditional dynamic balancing machine to work, which can effectively save the cost of human resources. And the measurement time of automatic positioning and dynamic leveling is only 3-5 seconds, which is several times faster than the traditional dynamic balancing machine. The operation is simple and you can go to work freely with simple training. Automatic positioning dynamic balancing machine to reduce manpower and control the beat of production more accurately, which is convenient for rhythmic production.

3. Precision of the rotor

The automatic positioning dynamic balancing machine has good measurement accuracy. When the automatic positioning dynamic balancing machine completes the measurement of the dynamic balance, the drive module stops the unbalance angle at the specified position on its own. The operator only needs to add the corresponding weight at the specified position. It can be retested and has high intelligence. And the measurement repeatability is stable, the data is more reliable, and the dynamic balance data of the rotor can be measured with high accuracy.

Because of the obvious advantages of the automatic positioning dynamic balancing machine, it has been widely used in the rotor manufacturing industry.

Zhuoxuanjin automatic positioning dynamic balance machine adopts advanced intelligent measurement method, which can intelligently and accurately measure the dynamic balance of different products. Greatly improve the efficiency and flexibility of factory logistics, and can minimize the product delivery cycle.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機轉(zhuǎn)子裝配工的一般操作規(guī)程如下: 1、工作前,整理場地,放穩(wěn)各零、部件,并檢查裝配使用工具和工作環(huán)境是否安全良好。 2、吊放電機機座、底板、定子、轉(zhuǎn)子、軸承等大型部件時必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.