Maintenance method and application advantages of automatic positioning dynamic balancing machine

Published:

2020-07-13 11:18

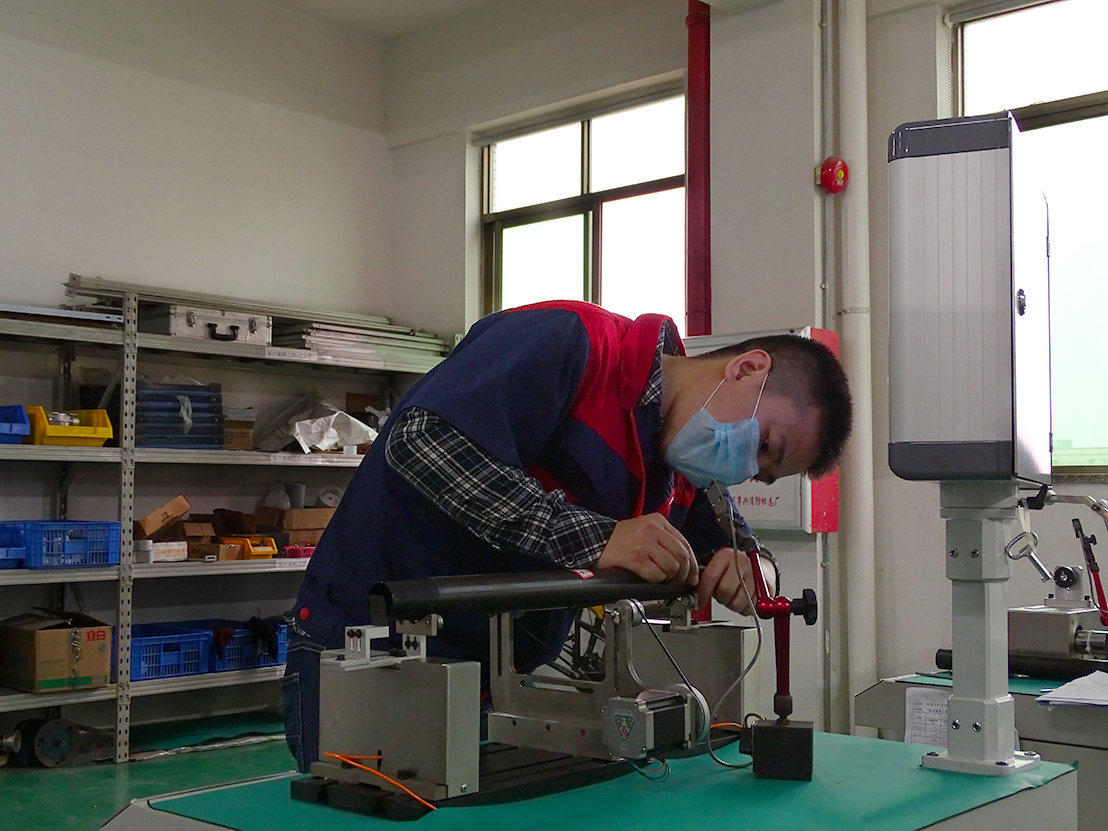

The rotor involves all walks of life, and the automatic positioning dynamic balancing machine is an indispensable product in the rotor production equipment and has huge market space. Various types of dynamic balancing machines are now used in many industries such as model aircraft, medical, beauty, mechanical processing, household appliances, power tools, new energy and so on. The following editor Zhuo Xuanjin introduces the maintenance methods and advantages of the automatic positioning dynamic balancing machine.

Maintenance method of automatic positioning dynamic balancing machine

Dynamic balancing machine for daily maintenance and maintenance, daily inspection: equipment appearance, support frame, equipment button, drive device, etc. If the dynamic balance machine fails and needs maintenance, you should contact the dynamic balance machine manufacturer in time to explain the fault situation of the dynamic balance machine (it is better to take pictures and shoot videos to the other party), and wait for the dynamic balance machine manufacturer to repair the fault site. Tools, materials and personnel should be given cooperation.

Note: It is better not to modify or disassemble the automatic positioning dynamic balancing machine without permission (if it must be modified, the consent of the dynamic balancing machine manufacturer must also be obtained and the opinions of the dynamic balancing machine manufacturer should be heard).

Application advantages of automatic positioning dynamic balancing machine

1. Good stability. The automatic positioning dynamic balancing machine adopts a high-precision sensing system, equipped with an organic combination of interference algorithms, etc., to accurately measure the rotor centrifugal force, strong measurement retest, small measurement error, and greatly improve product quality.

2. High degree of intelligence. Compared with the traditional dynamic balancing machine, the automatic positioning dynamic balancing machine has extremely high intelligence. No need to mark, no need for the operator to find the angle of unbalance. It can independently stop the measurement of the angle of rotor unbalance at the specified position. It is difficult to slow down the operation, reduce the error of rotor dynamic balance correction, and effectively avoid the error caused by the lack of operating experience.

3. High working efficiency. The measurement time of the automatic positioning dynamic balancing machine only needs 3-5 seconds, and the accurate measurement is carried out, which shortens the measurement time of the rotor dynamic balance and greatly improves the work efficiency.

In summary, it is the relevant information about the automatic positioning maintenance method and application advantages compiled by Zhuo Xuanjin editor, I hope to help everyone.

previous page

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機(jī)轉(zhuǎn)子裝配工的一般操作規(guī)程如下: 1、工作前,整理場(chǎng)地,放穩(wěn)各零、部件,并檢查裝配使用工具和工作環(huán)境是否安全良好。 2、吊放電機(jī)機(jī)座、底板、定子、轉(zhuǎn)子、軸承等大型部件時(shí)必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.