Car noise vibration may be the generator crankshaft dynamic imbalance

Published:

2019-06-15 14:58

Nowadays, family cars have entered the door of every household. It is difficult to avoid being troubled by various kinds of car faults. Drivers often ask: Why is the number of kilometers opened, my car engine noise is so big, the damage is so serious What? In fact, this is because everyone does not pay attention to the use and maintenance of the engine, causing the crankshaft to malfunction.

Crankshaft introduction

The crankshaft is a critical component in the engine that takes the force from the connecting rod and changes it to torque based on the crankshaft output and drives other accessories on the engine. The crankshaft is required to have sufficient strength and rigidity, and the surface of the journal needs to be wear-resistant, work evenly, and well balanced.

Crankshaft failure

1) Long-term high-load work. High-load operation causes the crankshaft to be fatigued for a long time. If the car or equipment is running slowly due to excessive load (such as long-term heavy-duty climbing), the crankshaft may be cracked or broken due to excessive torque. .

2) After starting, the load is running at high speed. At this time, the crankshaft is in a static state, because of gravity, the crankshaft is close to the bearing bush, and there is no oil film. If the engine runs at high speed immediately after starting, the oil film will not be formed immediately due to the oil lag. The crankshaft and the bearing bush may be "burned" due to dry friction and cause abnormal damage to the crankshaft.

3) The quality of the oil is not good. If the viscosity of the oil is too low or the oil quality level is insufficient, the oil pressure will be too low to cause an effective oil film. The shaft and the bearing bush may cause dry friction and cause the shaft to fail.

4) The balance of the crankshaft itself is poor.

Therefore, to extend the service life of our car, to have a comfortable driving environment, not only to learn engine maintenance, maintenance, but also to use the crankshaft dynamic balance machine to do the dynamic balance of the crankshaft.

How to improve engine crankshaft balance?

Ferrari and many European supercars use a flat-screw engine. The sound waves are strong and powerful. The excellent dynamic response makes the super-runners crazy. Although the plane crankshaft can provide a very good engine response, the beast will be heard when it is launched. The roar, but the engine with a flat crankshaft has a headache physical bottleneck, that is, annoying vibration. Although we can't remove the vibration, we can minimize the vibration according to the calibration of the crankshaft automatic positioning dynamic balance machine.

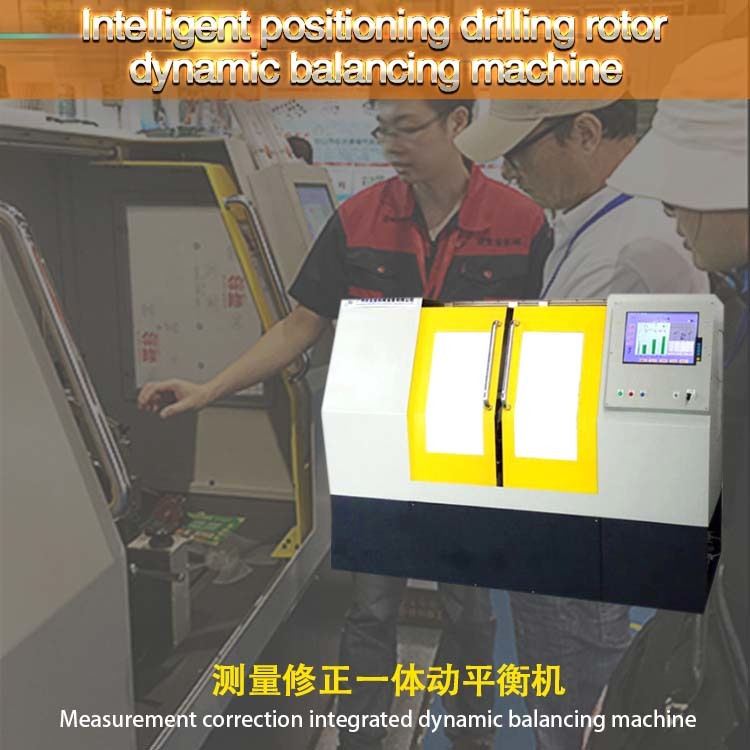

After analyzing the requirements of the automotive industry crankshaft and understanding the specific requirements of the crankshaft industry customers, Guangzhou Zhuoxuan Jin Dynamic Balancing Machine manufacturers selected Zhuo Xuanjin dynamic balance technology to develop and produce the crankshaft automatic positioning dynamic balancing machine. Zhuo Xuanjin's crankshaft dynamic balancing machine uses Zhuo Xuanjin's electric measuring system, which can be widely used in the dynamic balance correction of automobile four-cylinder crankshaft and six-cylinder crankshaft. The automatic positioning and balancing equipment can better meet the customer's mass production requirements.

The crankshaft is a key component in the automotive engine, and the dynamic balance of the crankshaft directly affects the performance of the engine. With the rapid development of China's automobile industry, the demand for crankshafts has also increased significantly. Therefore, the crankshaft batch balancing and improving the quality and efficiency of crankshaft dynamic balance have been paid attention to by engine and crankshaft manufacturers.

The crankshaft automatically positions the dynamic balancing machine to make the crankshaft balance no longer difficult.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機轉子裝配工的一般操作規程如下: 1、工作前,整理場地,放穩各零、部件,并檢查裝配使用工具和工作環境是否安全良好。 2、吊放電機機座、底板、定子、轉子、軸承等大型部件時必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.