The choice is the four points you need to know about the balancing machine.

Published:

2019-06-19 16:40

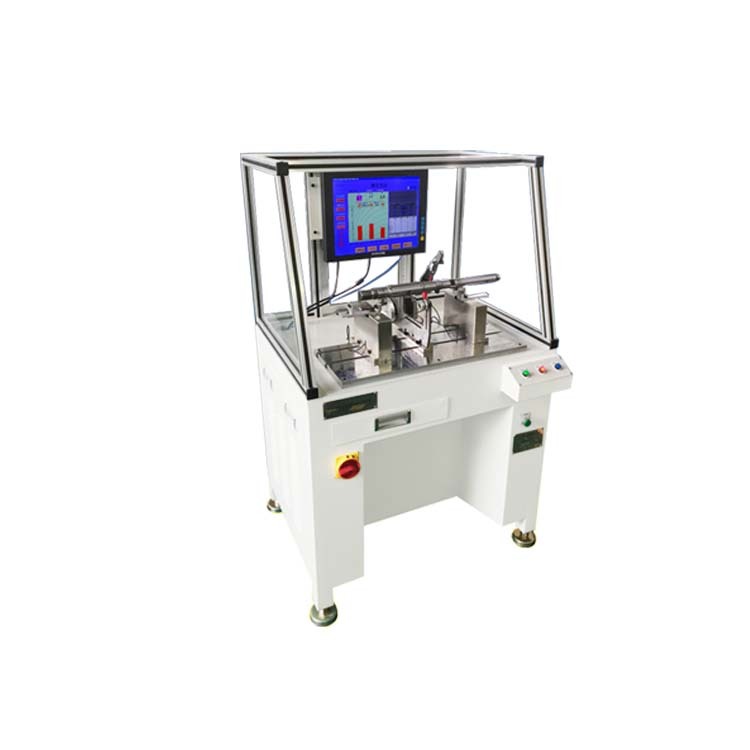

As a high-precision testing instrument, we should have the corresponding knowledge to operate correctly. Today, Xiaobian will explain the key points of the four related dynamic balancing machines.

4 points you need to know about the balancing machine

Working speed and balance speed

Balanced speed: The rotational speed of the dynamic balancing machine during the dynamic balance test. For the rigid rotor, under the standard conditions of ensuring precision, the lower rotation speed is selected as much as possible, that is, the dynamic balance machine is at the specified balance rotation speed. The amount of dynamic imbalance of the rotor can be measured at the highest efficiency. The magnitude of the balance speed is related to the quality and shape of the rotor. Under normal circumstances, the larger the rotor mass, the lower the balance speed, and the operating speed is not related.

2. Balanced speed and balance precision

A good dynamic balancing machine can correctly detect the amount of unbalance at the lower speed, rather than the higher the speed, the better the balance precision. For rotors of different quality and shape, we have to choose a different balance speed to achieve the maximum detection efficiency and precision of the dynamic balance machine.

3. Rotor mass and maximum load bearing quality of dynamic balancing machine

In the process of dynamic balancing machine selection, the rotor mass and the maximum bearing mass of the dynamic balancing machine are important reference indicators. Different quality rotors will use different types of dynamic balancing machines. The rotor mass is usually maintained at 25%-80% of the maximum load-bearing mass of the dynamic balancing machine. The dynamic balance machine has the best balance precision and balance efficiency, and the application life is the longest.

4. Rotor balance and working conditions

The dynamic balancing machine detects and corrects the unbalanced mass in the rotor mass, and ensures that the rotor reaches the minimum value of the dynamic unbalance within the mass range of the rotor under the existing dynamic balance technology. Rotor dynamic balance is the adjustment of the rotor's own mass range. Its precision and balance are not related. Just install the rotor correctly and you can use the equipment with confidence.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機(jī)轉(zhuǎn)子裝配工的一般操作規(guī)程如下: 1、工作前,整理場(chǎng)地,放穩(wěn)各零、部件,并檢查裝配使用工具和工作環(huán)境是否安全良好。 2、吊放電機(jī)機(jī)座、底板、定子、轉(zhuǎn)子、軸承等大型部件時(shí)必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.