How much do you know about the vertical balancing machine?

Published:

2019-06-20 11:44

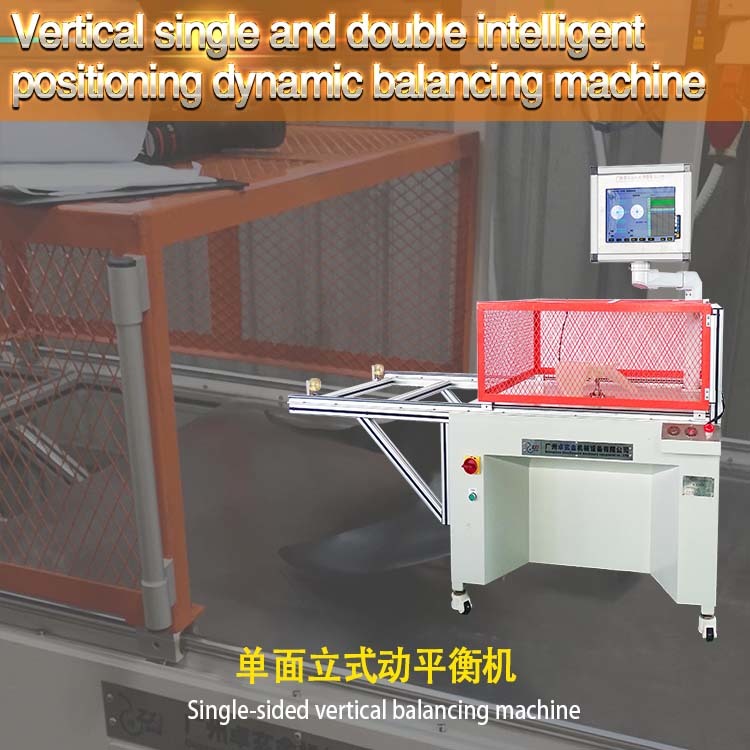

The vertical balancing machine refers to a balancing machine in which the drive spindle is a vertical installation. The vertical dynamic balance machine detection principle is basically the same as that of the general horizontal dynamic balance machine. There are also soft support and hard support, single or double-sided, but it is suitable for parts without a spindle. Its drive spindle is mounted vertically. It is suitable for detecting the dynamic balance measurement of brake discs, brake drums, saw blades, impellers, blades, flywheels, saw blades, etc. The calibration can be done by feeding method. The following is a brief introduction to the product knowledge of the vertical balancing machine.

All the rotors on the machinery and equipment used in the manufacturing industry rotate around its axis, precisely because of the uneven distribution of the mass distribution with respect to the axis, which causes centrifugal force. This type of unbalanced centrifugal force causes vibrations in the rotor bearings, which in turn causes noise and accelerates the loss of the bearing, which seriously jeopardizes the characteristics and service life of the product. Rotating parts such as motor rotors, machine tool spindles, internal combustion engine crankshafts, turbine rotors, gyro rotors and watch balances are subject to dynamic balance correction during the manufacturing process to operate smoothly and normally. Therefore, the vertical dynamic balancing machine can play a perfect role. The dynamic balancing machine can not only complete the problems caused by the work, but also the production quality is excellent, stable and reliable, and the price is low, which leads to the vertical dynamic balancing machine gaining many domestic and foreign Customer trust and support.

Single-sided vertical balancing machines and double-sided vertical balancing machines are two common vertical balancing machines that use the gravity of the rotor itself to detect static imbalances. If the rotor placed on the two horizontal rails has an unbalanced amount, its relative moment to the axis causes the rotor to roll on the guide rail until the unbalance is at the lowest position.

Correcting the imbalance of the rotor according to the data detected by the dynamic balancing machine can improve the mass distribution of the rotor relative to the shaft, and cause the vibration caused by the rotor during the rotation, that is, the vibration force acting on the bearing, thereby lowering to the allowable standard. Therefore, the vertical dynamic balancing machine is an indispensable measuring instrument for reducing vibration, improving characteristics and improving quality.

In general, the dynamic balance of the rotor contains two steps of detecting and correcting the amount of imbalance. The vertical balancing machine is suitable for detecting the amount of imbalance. The correction of the unbalance is usually done by drilling machine, milling machine and other auxiliary equipment (such as spot welding machine) or manually. The dynamic balancing machine calibration device has become part of the dynamic balancing machine.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

電機轉子裝配工的一般操作規程如下: 1、工作前,整理場地,放穩各零、部件,并檢查裝配使用工具和工作環境是否安全良好。 2、吊放電機機座、底板、定子、轉子、軸承等大型部件時必須放好方箱或墊木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.